manual dumbwaiter

A manual dumbwaiter is a simple yet effective mechanical device designed to move items between floors, offering a practical and efficient solution for various settings.

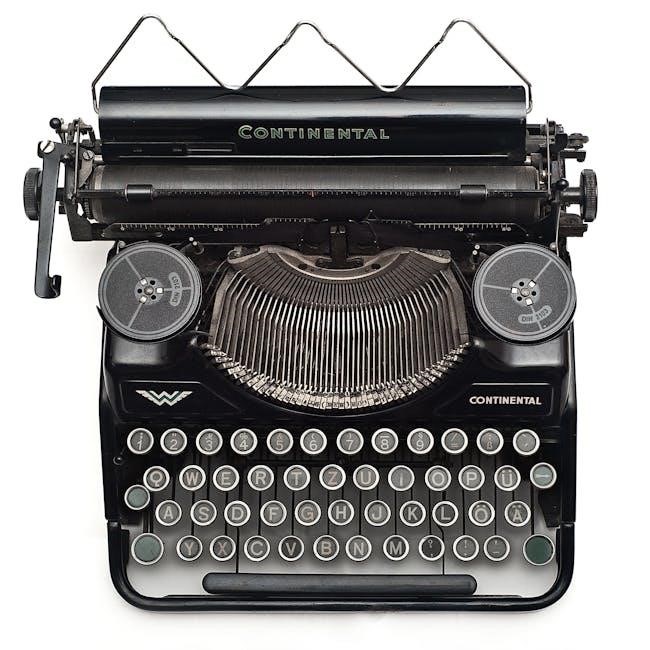

1.1 What is a Manual Dumbwaiter?

A manual dumbwaiter is a non-mechanical, hand-operated device used to transport items between floors in buildings. It typically consists of a platform or cart attached to ropes or chains, often with a counterweight to facilitate lifting; Historically, it was used in homes, restaurants, and hotels to move goods like food or laundry quietly and efficiently without the need for direct communication between floors. The term “dumb” reflects its silent operation, distinguishing it from speaking servants. While it offers advantages such as energy efficiency and space savings, it requires physical effort and has limitations in weight capacity and load size. Regular maintenance is essential to ensure smooth operation and safety. Despite modern alternatives, manual dumbwaiters still find niche applications in certain settings.

1.2 Historical Background of Dumbwaiters

The concept of dumbwaiters dates back centuries, with early versions used in large estates to transport food and goods discreetly. The term “dumbwaiter” likely originated from the “dumb” (silent) operation of these devices, which allowed servants to move items without being seen; Initially, dumbwaiters were simple rope-and-pulley systems, often powered by hand. By the 19th century, they became common in restaurants and hotels, streamlining service delivery. The rise of elevators in the 20th century reduced their prominence, but manual dumbwaiters remained popular in smaller buildings due to their reliability and low cost. Their enduring utility highlights their historical significance in facilitating efficient material movement across floors.

History of the Manual Dumbwaiter

The manual dumbwaiter traces its origins to the 17th century, evolving from simple pulley systems to become a staple in households and establishments for efficient goods transport.

2.1 Origins and Early Use

Manual dumbwaiters originated in the 17th century, emerging as simple pulley systems to transport goods vertically within buildings. Initially used in European estates and inns, they were designed to move items like food, laundry, and supplies between floors without requiring stairs. Servants operated these early systems, pulling ropes to lift or lower platforms, streamlining daily tasks. By the 18th century, dumbwaiters became a common feature in wealthy households, enabling efficient management of large estates. Their practicality made them indispensable for reducing physical effort and saving time, laying the groundwork for their widespread adoption in both residential and commercial settings. This early innovation marked the beginning of their enduring utility in vertical transportation solutions.

2.2 Evolution of Manual Dumbwaiters Over Time

The manual dumbwaiter has undergone significant transformations since its inception. Early versions relied on basic pulleys and ropes, while later designs incorporated more advanced mechanisms. Over time, materials like wood and iron gave way to steel and aluminum, enhancing durability and efficiency. The introduction of counterweight systems improved functionality, reducing the physical effort required to operate the device. Modern designs often feature bearings and smoother pulleys for quieter and more seamless operation. Despite technological advancements, the fundamental principle of manual operation has remained consistent, ensuring its relevance in various settings. Today, manual dumbwaiters are valued for their simplicity, reliability, and ability to adapt to different environments, making them a timeless solution for transporting goods between floors.

Design and Components

A manual dumbwaiter features a car moving along a track system with pulleys and ropes or chains for operation. Safety features like brakes or counterbalances are included to prevent accidents. This simple design enables efficient item transportation between floors.

3.1 Basic Design Overview

A manual dumbwaiter consists of a car that moves along a vertical or inclined track system. The car is typically made of durable materials like wood or metal, with an open or enclosed design. It is connected by ropes, chains, or cables to a pulley system, allowing users to pull the car between floors manually. The design is simple, focusing on functionality and ease of use. Safety features such as brakes or counterbalances are often incorporated to control the movement and prevent accidents. The system is compact, making it suitable for installation in tight spaces. This straightforward design ensures reliability and minimal maintenance, making it a practical solution for transporting items between floors.

3.2 Key Components of a Manual Dumbwaiter

A manual dumbwaiter consists of several essential components that ensure its smooth operation. The carriage, typically made of durable materials like wood or metal, holds the items to be transported. Connected by ropes or chains, it moves along a vertical or inclined track system. Pulleys, mounted at the top and bottom, guide the ropes and facilitate the lifting mechanism. A counterweight is often used to balance the load, reducing the effort required to operate the system. Control mechanisms, such as handles or levers, allow users to pull or lower the carriage manually. Additionally, safety features like braking systems or locks may be included to prevent accidents. Together, these components create a functional and efficient system for moving goods between floors.

Functionality and Operation

A manual dumbwaiter functions by using a pulley system to move items between floors, operated by pulling ropes or handles, offering a straightforward and efficient solution.

4.1 How a Manual Dumbwaiter Works

A manual dumbwaiter operates using a pulley system, where a rope or handle is pulled to move the car between floors. The system relies on counterweights to balance the load, making it easier to lift or lower items. Users place items into the dumbwaiter car, close the doors, and pull the rope to activate the movement. The pulleys guide the car along a vertical track, allowing items to be transported efficiently. This simple, non-motorized design ensures reliability and energy efficiency, as it does not require electricity to function. The manual operation makes it a practical solution for low-to-moderate use in both residential and commercial settings.

4.2 Daily Operation and Usage

Operating a manual dumbwaiter involves simple, repetitive steps to ensure smooth and efficient use. Start by loading items into the carrier, ensuring they are securely placed and within weight limits. Pull the ropes or handles gently but firmly to move the carrier between floors. Always check the direction of movement to avoid accidents. Unload items carefully, maintaining control of the carrier to prevent sudden drops. Regularly inspect the ropes and pulleys for wear and tear. Avoid overloading, as this can strain the system and lead to damage. By following these guidelines, a manual dumbwaiter can provide reliable service, making daily tasks easier and more efficient in both residential and commercial environments. Proper usage extends its lifespan and ensures safety.

Installation and Setup

Installing a manual dumbwaiter requires careful planning and preparation to ensure proper alignment and secure mounting, guaranteeing smooth operation.

5.1 Installation Process

The installation of a manual dumbwaiter begins with assessing the space to determine the optimal location. Next, the shaft is constructed, ensuring it aligns with the building’s structure. The dumbwaiter car is then placed inside the shaft, and pulleys are mounted at the top and bottom. Ropes or chains are attached to the car and connected to a hand crank or lever. Safety mechanisms, such as counterweights and braking systems, are installed to prevent accidents. Finally, the system is tested to ensure smooth operation. Proper installation is crucial for functionality and safety, so following manufacturer instructions is essential.

5.2 Tools and Materials Required

Installing a manual dumbwaiter requires specific tools and materials to ensure a safe and proper setup. Essential tools include a drill, screwdriver, wrench, pliers, and a measuring tape. Materials needed are wood or steel for the shaft, pulleys, ropes, and fasteners like screws and bolts. Additionally, a sturdy frame and counterweight are necessary for smooth operation. Safety gear such as gloves and goggles should be worn during installation. Optional items include an electric drill for faster assembly and a ladder for reaching high areas. It’s crucial to have all components pre-measured and ready to avoid delays. Always refer to the manufacturer’s manual for specific requirements and consider consulting a professional if unsure. Proper preparation ensures a reliable and durable dumbwaiter system.

Maintenance and Repair

Regular maintenance ensures smooth operation, with tasks like lubricating pulleys and checking ropes. Addressing minor issues promptly prevents major repairs, extending the system’s efficiency and reliability.

6.1 Regular Maintenance Schedule

A regular maintenance schedule is essential to ensure the optimal performance of a manual dumbwaiter. This includes weekly inspections of pulleys, ropes, and bearings. Lubricate moving parts every month to reduce friction and wear. Every quarter, check the alignment of the shaft and tighten any loose bolts or screws. Annually, inspect the rope for signs of fraying or damage and replace it if necessary. Additionally, clean the system thoroughly to remove dust and debris that may accumulate. By following this schedule, you can prevent breakdowns and extend the lifespan of your manual dumbwaiter. Regular maintenance also ensures safety and efficiency in daily operations.

6.2 Common Repairs and Tips

Common repairs for manual dumbwaiters often involve lubricating pulleys, tightening ropes, or replacing worn-out components like wheels or bearings. Regularly inspecting the system for wear and tear can prevent breakdowns. Tips include ensuring proper alignment of pulleys to avoid misloading, lubricating moving parts periodically, and checking ropes for frays or damage. Keeping the cart clean and free from debris also improves functionality; For safety, always test the system with a light load after repairs. Addressing issues promptly can extend the lifespan of the dumbwaiter and maintain smooth operation.

Safety Considerations

Always adhere to safety guidelines to prevent accidents. Ensure proper installation, avoid overloading, and conduct regular inspections to maintain smooth operation and minimize potential hazards or injuries.

7.1 Safety Guidelines for Use

Always follow proper safety guidelines when using a manual dumbwaiter. Ensure it is installed correctly and regularly inspected for wear and tear. Avoid overloading the system, as this can lead to mechanical failure. Use the correct lifting techniques to prevent strain or injury. Keep children away from the dumbwaiter and ensure all users understand its operation. Never leave items unattended while in transit. Regular lubrication of moving parts can reduce friction and prevent accidents. If any malfunction occurs, stop usage immediately and contact a professional for repairs. Adhering to these guidelines ensures safe and efficient operation, minimizing risks to users and property.

7.2 Potential Risks and Hazards

Manual dumbwaiters, while generally safe, pose certain risks if not used or maintained properly. Overloading the system can lead to mechanical failure or items falling, causing damage or injury. Improper installation may result in unstable operation, increasing the likelihood of accidents. Additionally, lack of regular maintenance can cause wear and tear on components, leading to unpredictable behavior. Users must also be cautious of moving parts, as fingers or clothing could get caught. Furthermore, improper use, such as transporting hazardous materials, can create additional risks. Lastly, children or pets may accidentally operate the dumbwaiter, leading to unintended consequences. Adhering to safety guidelines and proper maintenance is essential to mitigate these hazards and ensure safe operation.

Advantages of a Manual Dumbwaiter

Manual dumbwaiters offer cost-effectiveness, energy efficiency, and reliability, requiring no electricity while providing quiet operation and eco-friendly functionality for transporting items between floors effortlessly.

8.1 Convenience and Efficiency

Manual dumbwaiters provide unparalleled convenience by enabling quick and easy transportation of items between floors, eliminating the need for repetitive trips via stairs. Their compact design ensures they can be installed in tight spaces, making them ideal for homes, restaurants, and offices. By streamlining the movement of goods, they reduce congestion in hallways and stairwells, enhancing overall efficiency. Additionally, they minimize physical strain by reducing the need for manual lifting and carrying, which is particularly beneficial in busy environments. Their smooth operation and reliability make them a practical solution for daily tasks, saving both time and effort while ensuring items are delivered safely and promptly. This simplicity and effectiveness have made manual dumbwaiters a timeless choice for improving workflow and productivity.

8.2 Cost-Effectiveness

Manual dumbwaiters are a cost-effective solution for moving items between floors, offering significant savings compared to automated systems. Their simple design reduces installation and maintenance costs, while their durability ensures long-term reliability. Without the need for electricity, they minimize energy expenses, making them an economical choice for small businesses, restaurants, and homes. The absence of complex machinery lowers initial and ongoing expenditures, providing excellent value for everyday use. This practical approach ensures that manual dumbwaiters remain a financially sensible option for those seeking efficient, no-frills transportation of goods within a building. Their affordability and low operating costs make them a smart investment for both residential and commercial settings.

Limitations of a Manual Dumbwaiter

Manual dumbwaiters have limitations, including weight and size constraints, restricting heavy or bulky loads. They also require physical effort, making them less suitable for large-scale operations.

9.1 Weight and Size Limitations

Manual dumbwaiters are designed to handle specific weight and size restrictions, typically ranging from 50 to 500 pounds, depending on the model and construction materials. Exceeding these limits can damage the system or lead to mechanical failure. The size of items is also constrained by the dimensions of the dumbwaiter car and the shaft, making it unsuitable for large or oversized objects. These limitations ensure safe and efficient operation, preventing overloading and potential accidents. Users must adhere to the manufacturer’s guidelines to maintain functionality and longevity. Understanding these constraints is essential for selecting the right dumbwaiter for specific needs and avoiding operational issues. Proper planning and adherence to weight and size limits are crucial for optimal performance.

9.2 Physical Effort Required

Manual dumbwaiters require consistent physical effort to operate, as they rely on human power to move items between floors. This can be tiring, especially for frequent use or heavy loads. Users must pull ropes, crank handles, or push platforms, which demands strength and endurance. Over time, this repetitive motion may strain muscles, particularly for those with physical limitations. While the system is simple, the physical demands make it less suitable for individuals with mobility issues or for environments requiring high-efficiency transportation. Despite this, the manual operation keeps costs low and ensures reliability without electricity. However, it is essential to consider the user’s ability to handle the physical workload before installing a manual dumbwaiter.

Modern Applications

Manual dumbwaiters are now used in residential and commercial spaces for efficient item transport between floors, ideal for homes, restaurants, and small businesses seeking cost-effective solutions.

10.1 Residential Use

Manual dumbwaiters are increasingly popular in modern homes for their convenience and efficiency. They are often used to transport groceries, laundry, or other items between floors without the need for stairs. This system is particularly beneficial in multi-story residences, saving time and effort. Compact and space-efficient, manual dumbwaiters can be easily integrated into home designs, even in smaller properties. Their quiet operation ensures minimal disruption to daily life. Additionally, they are a cost-effective alternative to elevators, requiring less installation and maintenance. For homeowners seeking practical solutions to enhance their living spaces, manual dumbwaiters offer a reliable and user-friendly option. Their versatility makes them a valuable addition to both traditional and contemporary homes.

10.2 Commercial and Industrial Use

Manual dumbwaiters are widely utilized in commercial and industrial settings for efficient material handling. In restaurants, they transport food and dishes between floors seamlessly. Hospitals employ them to move medical supplies and laundry, ensuring hygiene and efficiency. Libraries use dumbwaiters to transfer books between floors, reducing manual labor. Industrial facilities leverage them to move tools, parts, and equipment, enhancing workflow. Their compact design and reliability make them ideal for high-traffic environments. By minimizing manual effort, they improve productivity and reduce operational costs. Customizable to specific needs, manual dumbwaiters remain a practical solution for businesses seeking to streamline operations while maintaining simplicity and cost-effectiveness.

Cost and Budgeting

Manual dumbwaiters require an initial investment for purchase and installation, but they offer long-term savings through reduced energy consumption and lower labor costs over time.

11.1 Initial Investment

The initial cost of a manual dumbwaiter includes the purchase of the unit, materials, and installation fees. Prices vary depending on the size, capacity, and features of the system. Basic models with standard lifting capacities are generally more affordable, while larger or custom designs can be more expensive. Additionally, installation costs may include labor fees for professionals, especially if structural modifications are needed. While the upfront expense may seem significant, it is a one-time investment that provides lasting functionality and convenience. Proper planning and budgeting are essential to ensure the chosen system meets both financial and operational requirements effectively.

11.2 Long-Term Savings

A manual dumbwaiter offers significant long-term savings, primarily due to its low energy consumption and minimal maintenance requirements. Unlike automated systems, it relies on manual operation, reducing electricity costs over time. This eco-friendly approach not only cuts down on utility bills but also minimizes the need for costly repairs or replacements. Additionally, the durable construction of manual dumbwaiters ensures a longer lifespan, further enhancing their cost-effectiveness. Over the years, the initial investment is offset by the consistent savings in energy, maintenance, and operational expenses. This makes a manual dumbwaiter a financially sustainable choice for both residential and commercial settings, providing reliable service while keeping long-term costs remarkably low.

Environmental Impact

Manual dumbwaiters are energy-efficient, requiring no electricity and reducing carbon emissions. Their eco-friendly design promotes sustainability by minimizing environmental impact while maintaining functionality over time.

12.1 Energy Efficiency

Manual dumbwaiters are highly energy-efficient as they operate without electricity, reducing overall energy consumption. By relying on manual effort, they minimize reliance on non-renewable energy sources, lowering carbon footprints. This eco-friendly design ensures sustainability and supports green building practices, making them an environmentally responsible choice for transporting items between floors. Their simplicity reduces the need for energy-intensive manufacturing processes, further enhancing their environmental benefits. Overall, manual dumbwaiters offer a practical solution that aligns with energy conservation goals while maintaining functionality.

12.2 Sustainability and Eco-Friendliness

Manual dumbwaiters are inherently eco-friendly as they rely on manual operation, eliminating the need for electricity. This reduces energy consumption and carbon emissions, making them a sustainable choice. Durable materials like steel or wood ensure longevity, minimizing waste. Regular maintenance prolongs their lifespan, further reducing environmental impact. They also promote efficient use of space, reducing the need for large, resource-intensive transportation systems. Overall, manual dumbwaiters offer a practical, low-impact solution for moving items between floors, aligning with eco-conscious values and sustainable living practices. Their simplicity and energy efficiency make them a environmentally responsible option for both residential and commercial settings.